vumz@vumz.sk

An innovative approach to the processing of kitchen waste and BRKO

Nowadays, environmental sustainability is becoming more and more important and therefore new technologies and approaches to waste treatment are being developed. One of these innovative solutions is the hygiene container that we designed. It is a revolutionary step in the processing of biodegradable municipal and kitchen waste, and gives the waste a second life as high-quality compost.

Revolutionary container design

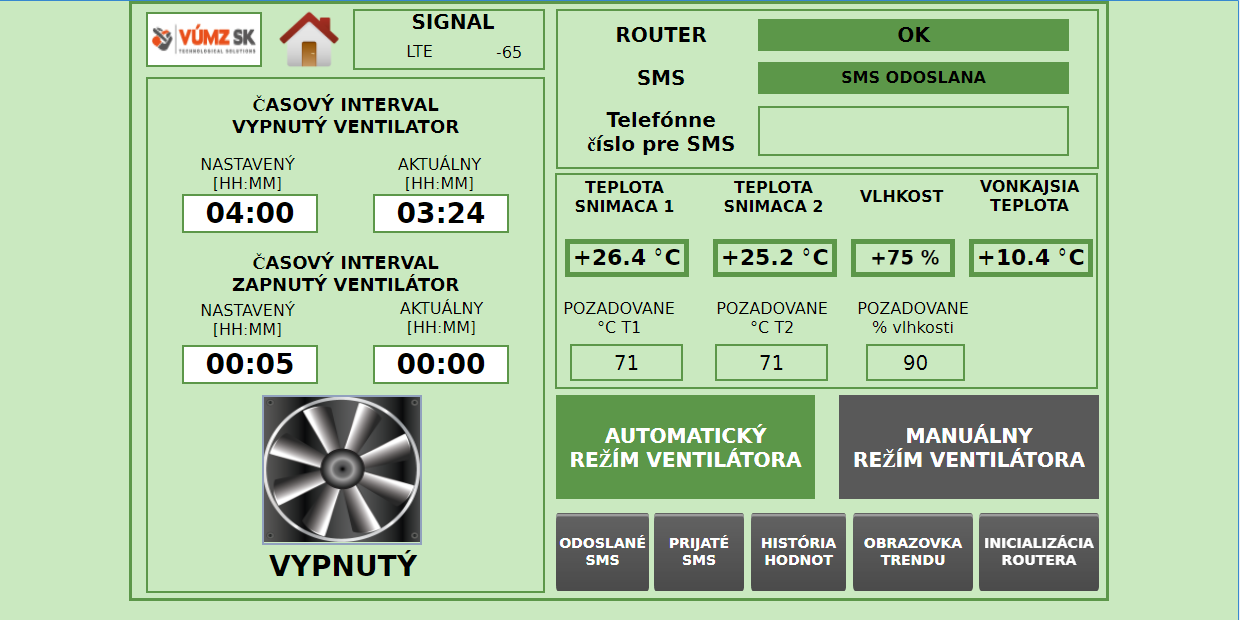

Our hygiene container is characterized by various top features that make it exceptional. Its body consists of a closed abrol container with a volume of 20 m³, which ensures sufficient space for processing a large amount of waste. The container is equipped with a fan and a heating coil, which allow ventilation and heating of the contents. All of this can be controlled manually or automatically using a programmable logic controller (PLC), which ensures precise control over the entire process.

Temperature and humidity control

To ensure effective sanitation the container contains two temperature sensors that are inserted into the waste pile, and a humidity sensor that measures the humidity inside the container. Another temperature sensor is located outside on the switchboard and monitors the outside ambient temperature. All these data are displayed on the 5-inch PLC display, where it is possible to monitor current temperatures, set the fan, heating coil and other parameters.

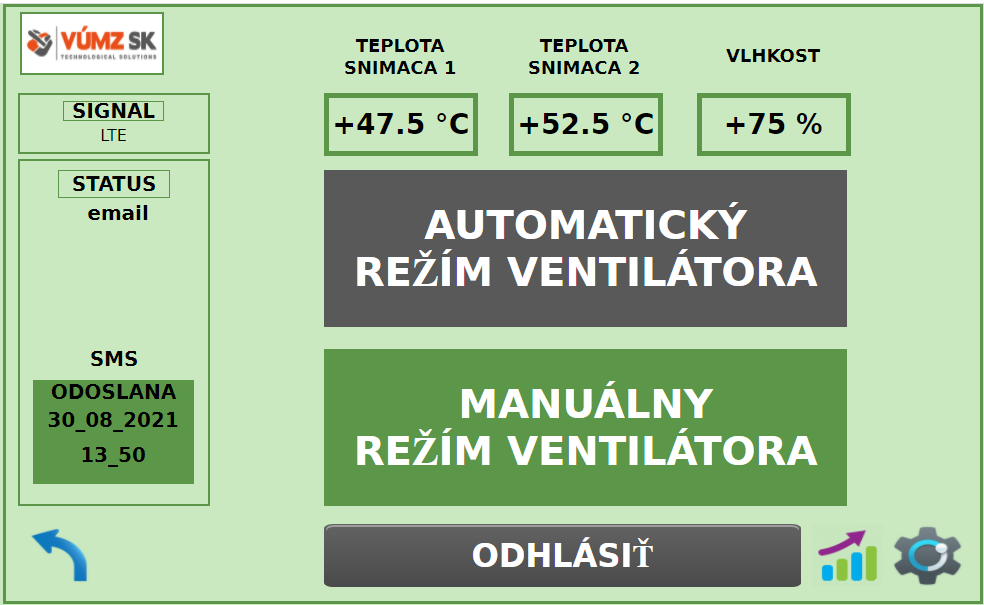

Remote access and control

The biggest innovation is the possibility of connecting the PLC to the Internet via Ethernet or a SIM card. In this way, the PLC can be remotely accessed and the container controlled, opening the door for further time and cost savings. The operator can remotely monitor the condition, change settings and ensure optimal conditions for sanitation.

Accelerated process and quality compost

After the adjustment, we achieved a significant reduction in the time required for sanitization, from the original 4 days to 1 day. This means that the sanitization process is considered complete when the maintained temperature reaches 70 degrees for at least one hour.

An important change that contributed to this shortening was the change in the roof of the container. It originally consisted of two manually removable parts, which caused unnecessary heat leakage. We eliminated this inefficiency by replacing the roof with a fully closable structure, which is controlled using a lever located on the side of the container. This change not only ensured more effective sanitation, but also improved the overall insulation of the container, which minimizes heat loss and increases the efficiency of the entire process.

After such a process, a sample is taken and if everything is in order, a very high quality compost can be created, which is in high demand and contributes to environmental sustainability.

-

Hygienizačný kontajner pred úpravou strechy

Button -

Hygienizačný kontajner pred úpravou strechy

Button -

Hygienizačný kontajner po úprave strechy

Button -

Hygienizačný kontajner po úprave strechy

Photo By: John DoeButton

Energy efficient

Our hygiene container is connected to 230V, which enables energy-efficient operation. In this way, we minimize the environmental impact of the process and ensure its sustainability.

The overall goal of our project is to improve and speed up the waste sanitation process, which will help us achieve environmental sustainability and create quality compost. Our sanitation container is an example of how innovation can change the way we care for our planet while achieving practical benefits.